We Restored our 70-year-old Slot Machine!

We have come a long way since our first article that we published back in February, in which we explained the backstory of our Beromat slot machine restoration project. After that cold and foggy morning we continued on with our mission to restore the device, which brought us to our second article in which we disassembled it completely.

Now, almost six months later, we’re finally entering the third and last step where we’re going to completely restore the machine to its former beauty, and we can’t wait to explain you the process and show all the photos! Let’s start off from the beginning…

Five simple tools and a delicate touch are more than enough to start

Our restoration technician caught us off guard when he came in to start working on the machine. We expected him to come out guns blazing with all kinds of elaborate tools and an enormous specialist apparatus. But he turned up carrying all of his tools in one hand!

Scraper, chisel, sandpaper (used either by hand for a smaller area or in combination with a pneumatic polisher/grinder for bigger ones), air spray gun, and a hand brush… that’s it! A basic set of tools and a professional’s touch was all we needed to make our slot machine as good as new.

With all the tools ready on the workbench, there were four crucial things to do. Firstly, the slot machine needed proper cleaning. The next step was to strip down the old paint and mend any potential damage due to age and improper handling, both on the metal and wooden components. The third step saw us painting the sanded surfaces, while the fourth and final step was making new labels and reassembling the machine.

Break it, sand it, fill it, fix it and then repeat it

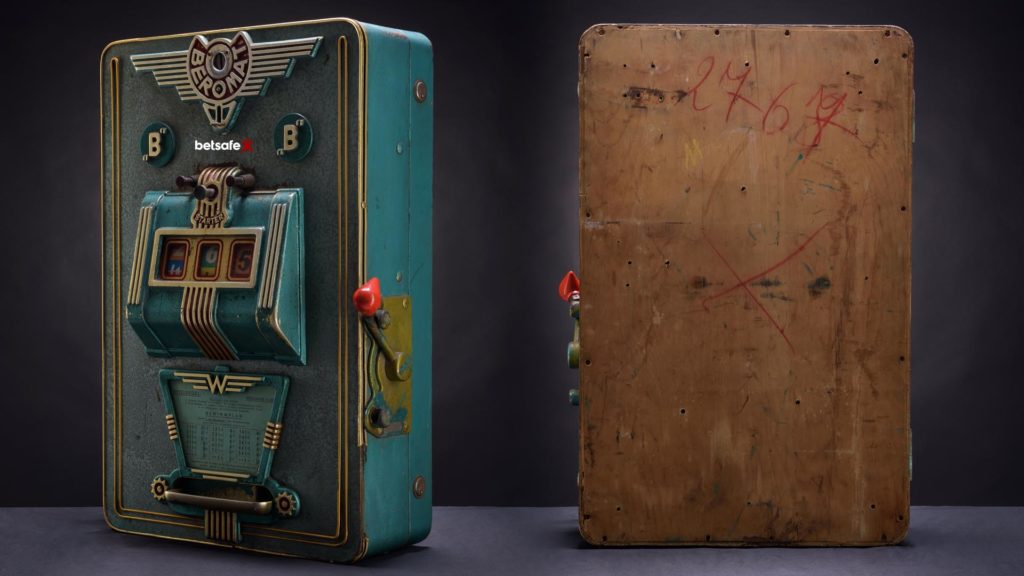

After sanding all the metal parts, which were in good shape and shone like a glazed donut afterwards, we moved on to the wooden parts of the casing. As we went deeper with this fixer-upper, we noticed that the back part of the wooden door was in a really bad shape. So, we decided to scrap it altogether, keep the outer frame, and make a new back panel using the same MDF material type as in the original one.

Having checked that off the list, the next thing to do was mend the rest of the wooden casing using a filler compound. We applied the blend – a paste-like mixture made from various elements that dry out and firm up – into the cracks created by either stripping the wood or smoothing out the surface scratches and other imperfections.

And this is where we found ourselves sanding, filling, fixing, sanding again, filling again… you get the idea. You go around in circles, rinse and repeat, until you’re satisfied with the result – an even, flat surface, or a specific contour or bend, such as on the edges of the frames where they slightly hug around the corner.

So, after all the polishing, the slot machine’s casing was super smooth and clean, like a blank canvas. And what do we do with blank canvases? Why, we paint them, of course!

Making our unique paint mixture

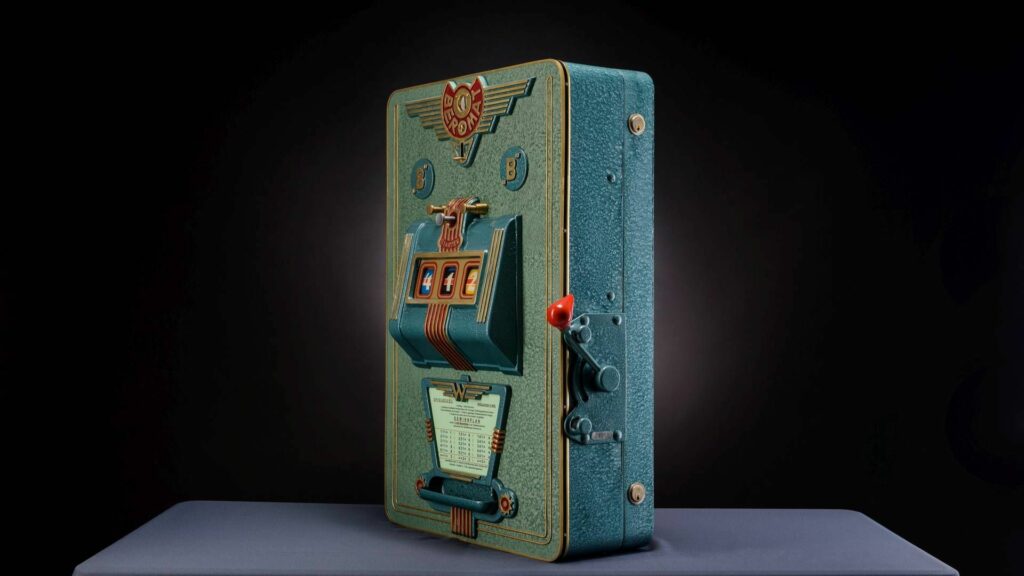

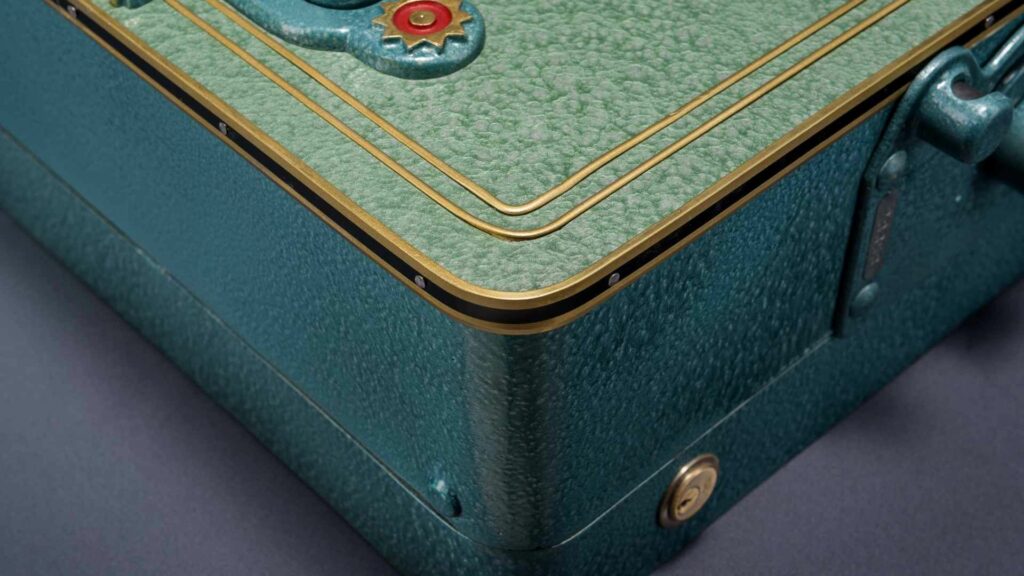

Beromat slot machines have a unique aquamarine colour with many details thanks to the texture that looks like dispersed waterdrops. All in all, it’s anything but an off-the-shelf buy when it comes to the paint. That’s why producing the right colour was an especially important task. To colour-match it properly, you have to go through a four-step process.

First, you choose the general direction of the colour, with two or three different shades. Then you narrow down the selection by comparing the colour samples against the original colour in various lights and under different angles. Once that’s done, the next step is determining the colour’s texture and grain, which was especially important in our case because of the unique surface that the paint would be applied to. The last step is to mix the final colour based on those parameters, compare the samples against the original, and make adjustments if needed.

What’s particularly interesting about our slot machine is that it has two different colour gradients. The side frame is a bit blue-ish, while the shade in the front leans more towards green. This difference is clearly visible, even in photos.

However, that was not even the challenging part in our case. As we mentioned, there was a specific wavey texture to the colour, and we were able to recreate it by mixing it with some paint thinner and applying it in multiple coats.

As we applied the paint, the texture had that rough, inverse-bubbly feel to it, sort of like dried-up droplets of water in the sand. Some of the smaller parts of the slot machine were of different colours, and in some cases, were too tiny to paint using the airbrush. So, we had to take a different approach.

That moment when the hand brush comes to action

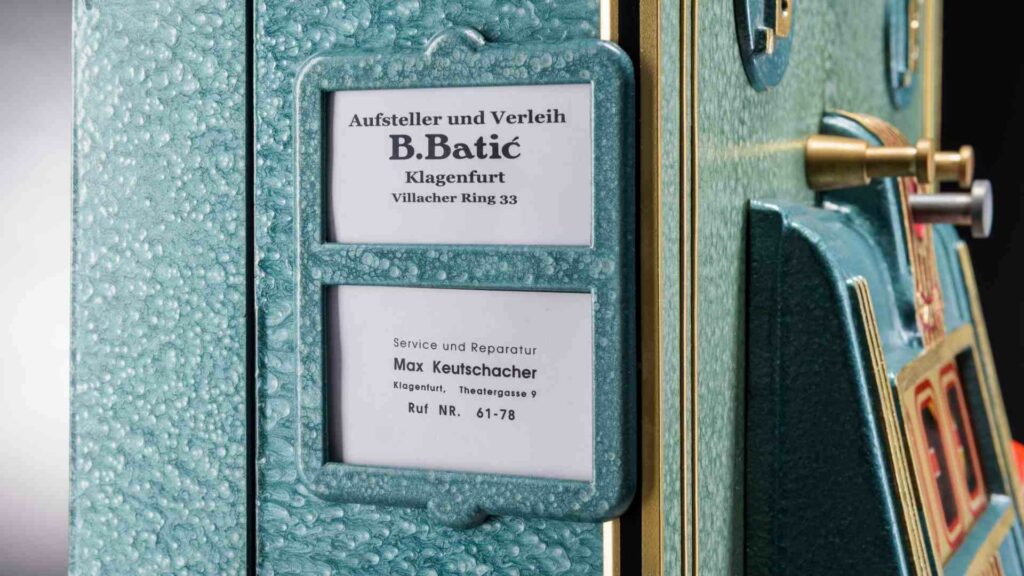

Besides using an air spray gun to lay the paint onto the outside of the machine’s casing, we also used a fine hand brush for some of the metal pieces. We used it on the decorative moulding on the front side (we recreated the moulding from aluminum), on the two “B” badges, the coin deposit system, the game start handle, and in a few other places. That’s why you’ll see many imperfections on most of these slot machines, even on the original work – every slot machine that came out of the factory had the personal touch of the worker who assembled and painted them. So, in a way, everything was custom made.

In this process you will certainly need a steady hand, and that was the main challenge we faced when applying the paint. We also had to make sure we apply the right colour to the right parts. Many of them were in such a bad shape that we first needed to determine what the original colour even was.

For example, the bottom coin tray was completely covered in gold paint, but if you look at our photos from the first article, you could easily mistake it for a different colour.

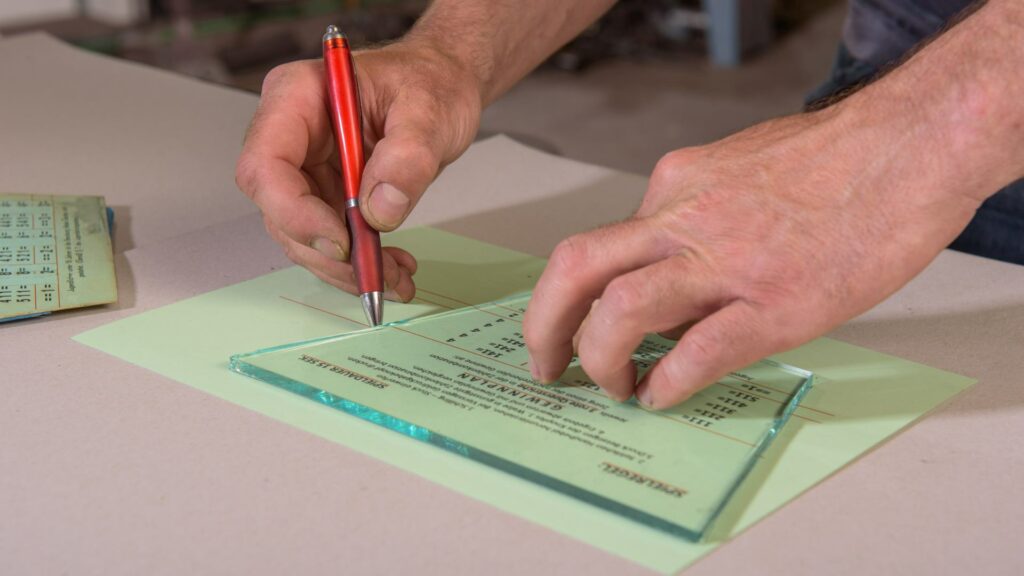

Recreating the original labels from the “nose” of the machine

No, we haven’t forgotten about them! Unfortunately, time had done a number on the labels, as we expected, so we had to make new ones. This included everything from colourful labels on the reels to the big rule book and service cards. Naturally, we used the original parts as much as possible as templates for colouring new ones. Here we would especially mention the glass “display” with the gold-painted frame, which we recreated using these templates.

It’s a demanding balancing act, where you try to copy the original label visuals as accurately as possible. Still, in a modern production environment, the advanced printer technology can sometimes create a rather unnatural look and feel. Thankfully, our experts were more than capable of solving this problem, as they deal with this issue regularly.

Once we put the new labels side-by-side with the originals, it was hard to tell which ones were which. The only tell-tale sign was, of course, the deteriorated condition of the originals.

Putting everything back together, with a big surprise at the end

It’s easy to pull things apart, but not many people will volunteer to take on the challenge of putting everything back together. But you gotta do what you gotta do… Of course, we let the restoration technicians take on that fun job this time to make sure we don’t scuff anything. But we were on hand to provide them with guidance in case they got stuck!

Kidding aside, since this slot machine has a straightforward mechanism, putting everything back together wasn’t actually a big problem. It’s a reverse process compared to the disassembly: we started with the smaller details on the outside of the casing, from the two “B” badges and “wingman” signs to the side duck-beak handle.

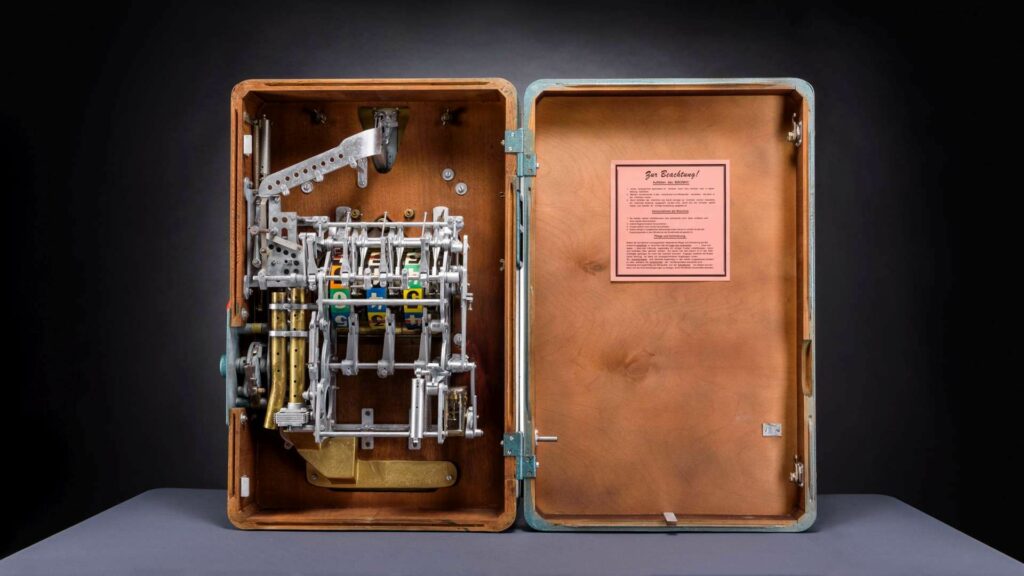

Everything slotted in just as quickly and easily as it had come out. As for the reels, which we also called the “brain” of the whole thing, we just slotted them back into the giant contraption, mounted into its center spot, connected the handle and the timing mechanism, and that was it. The back door was ready to be mounted and closed.

And no, we didn’t end up with any extra screws!

The best part? After we applied our special assembling touch and double-checked that everything is in order, mechanically speaking, the slot machine came back to life! By that, we mean it worked! You don’t even have to put any coins in it as it has a “free to play” mode! You can just pull the handle and the reels start to spin, and after a while, they stop one by one. It’s a whole different kind of experience.

Finally done and ready for our next project

A thing of beauty, isn’t it? Our slot machine came back to life, as good as when it was first used back in the 1950s. Comparing the before and after photos gives you an even better idea about how remarkable this transformation really is. Every detail in the process received a personal touch, and the craftsmanship is impeccable. We’re sure that the original creator would shed a tear or two seeing his product still going strong, even 70 years after it was shipped from the factory.

We’re now transferring our Beromat to our offices, and it will be used as a background in our future Betsafe Canada YouTube channel studio. So, stay tuned, and be sure to follow us on our blog!